The „Extension of the Technology Incubator and the Podkarpackie Science and Technology Park Service Centre – PSTP – Stage 3” project was implemented as the next phase of the establishment of the Podkarpacki Science and Technology Park and continued earlier investment initiatives:

-

The “Establishment of the Podkarpackie Science and Technology Park (PPNT) – Stage 1” project

-

The „Development of the Podkarpackie Science and Technology Park Service Centre (PSTP) – Stage 2” project

The „Extension of the Technology Incubator and the Podkarpackie Science and Technology Park Service Centre – PSTP – Stage 3” project was implemented within the framework of the Development of Eastern Poland Operational Programme 2007 -2013, Priority I. Modern Economy, Action I.3 Supporting Innovation, co-financed by the European Regional Development Fund and the state budget

Project duration: Jan 01, 2014 – Dec 31, 2015.

Project budget: PLN 27,842,881.79 (total costs):

-

eligible costs: PLN 22,787,471.21, incl. own contribution of PLN 3,533,881.04

-

grant: PLN 19,253,590.17

The actual eligible costs at the completion of the project were PLN 22,787,471.21.

The Grant Agreement was signed with the Polish Agency for Enterprise Development on Jan 29, 2015 and then was annexed twice.

The project objective:

The key objective of the project is to develop a competitive knowledge-based economy and to improve innovation-driven business attractiveness of the Podkarpackie Region through strengthening, developing and extending the research and infrastructural potential of the region.

This objective was achieved by:

- preparation of infrastructural and organizational background – construction of the Hall IV (IT 4) necessary to provide support services leading not only to a creation of new enterprises that will demonstrate a high potential for growth in a specific and competitive environment but also to the development of existing businesses.

- enhancing and supplementing the existing research base crucial to increase the innovation-driven competitiveness of enterprises; this goal will be achieved through establishment of an AEROPOLIS laboratory (the Laboratory of Materials Science and Prototyping), provided with high-class equipment that enables rendering professional research services for industry.

The project is destined primarily for small and medium-sized enterprises operating in the Podkarpackie Science and Technology Park AEROPOLIS, but participation of companies from Podkarpacie and other regions of Poland, as well as foreign investors is also encouraged. The participants of the project will be offered an opportunity to rent space in the Hall IV on preferential terms and to benefit from the services of the newly-created laboratory.

Project scope:

The scope of the Extension of the Technology Incubator and the Podkarpackie Science and Technology Park Service Centre – PSTP – Stage 3” project was:

-

The construction of the Hall IV premises with surrounding sites, pavements and a parking lot of total area of 3,910.30 m2,

-

delivery of specialized equipment and furniture to the AEROPOLIS laboratory,

-

delivery of office furniture, computers and multimedia equipment.

Location:

The Local District of Trzebownisko, District of Rzeszow, the Podkarpackie Science and Technology Park, S1 Zone,

Address: Jasionka 954 E,

36-002 Jasionka

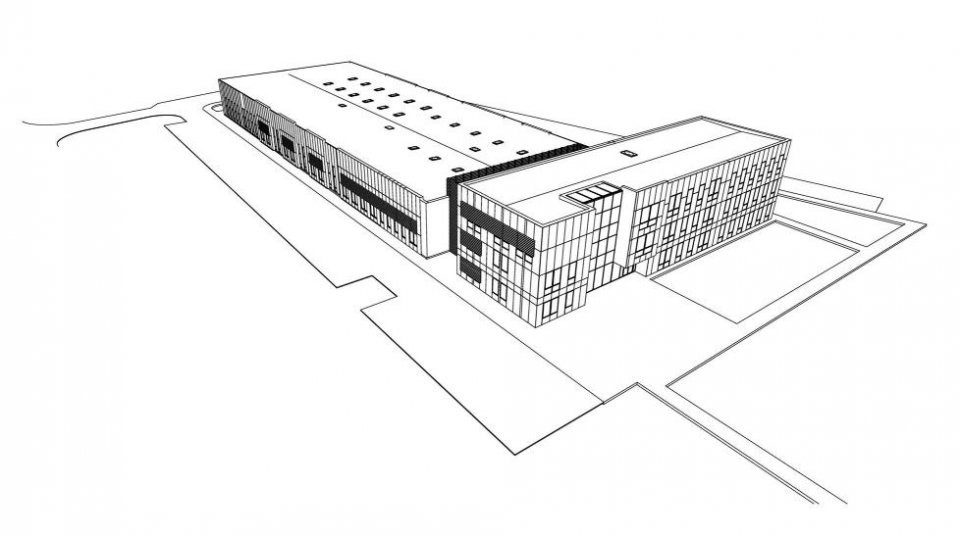

The Hala IV facility (Technology Incubator – IT4) consists of two functionally connected premises:

-

a one-storey production and research building

-

a three-storey administrative building with a two-storey connector.

The production and research area comprises 13 independent units, of which 10 units may be rented by start-ups while in the remaining three the AEROPOLIS Laboratory of Materials Science and Prototyping equipment was installed.

The production and research area comprises:

-

1 prototyping and laboratory unit of area of 187.85 m2 and 2 production and research units of areas of 155.20 and 161.15 m2, respectively, equipped with laboratory devices and managed by the PSTP Support Centre,

-

1 production and research unit of area of 197.65 m2 that is available for rent,

-

4 production units of area of 200 m2 that are available for rent,

-

5 production units of area of 155 m2 that are available for rent.

The administrative area includes:

-

the management office (3 rooms of total area of 90 m2),

-

20 office rooms of area of about 26 m2 that are available for rent,

-

open-space offices of area of 139.20 m2 that are available for rent

(5 workstations for 1 person, 4 workstations for 2 persons, a conference room for 10 persons) -

training room I for about 48 people

-

training room II for about 25 people

-

a conference room for about 16 – 20 people

-

a mini-cafeteria for about 16 people

-

dressing rooms for employees

-

a cafeteria for 40 people

Equipment available in the administrative area of the IT4 (Hall IV) building and in the open-space area:

- furniture: cabinets, bookshelves, tables, chairs, desks, document storage containers,

- IT and multimedia equipment: computers with software, laptops, copying machines, all-in-one printers, image projectors.

Equipment of the AEROPOLIS Laboratory of Materials Science and Prototyping:

-

A 3D printer using a rapid prototyping technology where polyamide powder is subject to laser sintering, provided with dedicated software and accompanying accessories.

-

A 3D printer using a 3 SP technology which advantages include: The possibility to make models that can be used directly in specific tasks where precision is of crucial importance; the possibility to make models directly for Vacuum Casting purposes; the possibility to use thermos-resistant materials, a non-devaluing technology (patents from 2013); possibility to make fully transparent and wax-imitating materials (ABS, ABS/PC, PP, PC) for the electromechanical industry,

-

An environmental chamber with a lighting system, designed for testing according to IEC 61215 (p. 10.11 + 10.12 + 10.13) and IEC 61646 (pkt. 10.11 + 10. 12 + 10.13). The chamber enables sample irradiation within the visible light range, UVA and UVB, which conforms to the requirements of European standards on photovoltaics and construction materials.

-

An optical measurement system that is suitable for any application when high-quality measurements are needed or when extreme conditions prevent sufficiently quick and precise digitalization. The system includes: measuring head, software, control unit, mobile workstation, additional accessories, working utilities.

-

An X-ray fluorescence spectrometer with energy dispersion designed for quick and non-destructive on-site analyses. It can be used to analyse harmful substances according to RoHS/WEEE; to determine the composition of alloys or the concentration of heavy metals in soil and to analyse precious metals or minerals.

-

A thermographic measuring system (2 thermographic cameras) allow the possibility for a touch-free measurement of temperature in different locations on an object. Temperature is a parameter that often changes long before a failure. The possibility of remote measurements without good lighting and visibility (smoke, fog) makes thermographic cameras a broadly applied solution in various areas of science and industry.

-

A metallographic microscope with a camera, software and a printer and accessories to prepare samples.

-

A CO2 laser plotter – a machine for precise and quick engraving and cutting various materials (plexi, wood, laminates, textiles, plastics, leather, rubber).

-

Laboratory furniture and small equipment (a fume hood, laboratory and weighing tables, a wash stand, cabinets, scales, an eyewash station, an ultrasonic cleaner).

The laboratory equipment (devices) purchased under the „Extension of the Technology Incubator and the Podkarpackie Science and Technology Park Service Centre – PSTP – Stage 3” project is covered by a service package including calibration, recalibration, warranty, after-sales support, and technical assistance, valid through the entire project durability period, which is five years – until 2020. The workplaces are provided with adequate facilities.

Services that can be provided by the AEROPOLIS Laboratory of Materials Science and Prototyping:

-

touch-free coordinate measurements,

-

3D digitalization in a reverse engineering process,

-

ageing test,

-

metallographic tests,

-

non-destructive elemental analysis based on the XRF method for testing product compliance with the RO Hs Directive,

-

rapid prototyping services using SLS and 3SP technologies,

-

process engineering tests, thermography.

On Dec 16, 2015 the project closing conference was held in the premises of the PPNT Technology Incubator. On this occasion awards were handed to the Laureates of the 16th Edition of the Podkarpacie Innovator Contest (2015) in three categories: micro-, small- and medium-sized enterprises. The AEROPOLIS Laboratory services were promoted by experts representing business and scientific circles. A speech was also delivered by the Vice-President of the Polish Agency for Enterprise Development, Ms. Teresa Kubas – Hul. Among the guests of the closing conference were the representatives of the Podkarpackie Province authorities, members of the Province Parliament, the President of Rzeszów and representatives of the Rzeszów Municipal Office, representatives of the Province Authorities, the Rzeszów District Governor (Starosta), representatives of regional higher education institutions: the Rzeszów University of Technology and the University of Rzeszów, business experts, entrepreneurs, scientists collaborating with business, science and technology parks and incubators from Eastern Poland, the winners of the 16th Edition of the Podkarpacie Innovator contest and many other distinguished persons who showed their interest in cooperation with the AEROPOLIS Laboratory.